Films

Classic – Foils

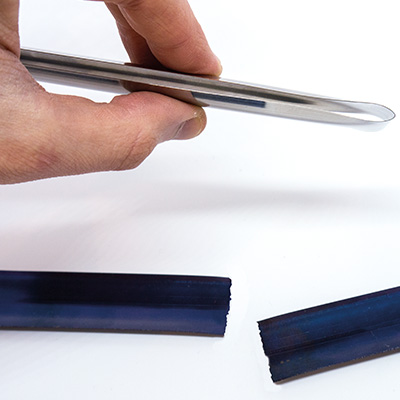

Most of our reflectors are produced from material, which is 100% free from potentially hazardous phthalates. We have a strict environmental policy and have implemented a stringent health and safety system. The reflective materials consist of micro prisms, which are applied onto a flexible, UV-stabilized polymer coating. The materials can be connected with compatible textiles by sewing procedures or using special welding.

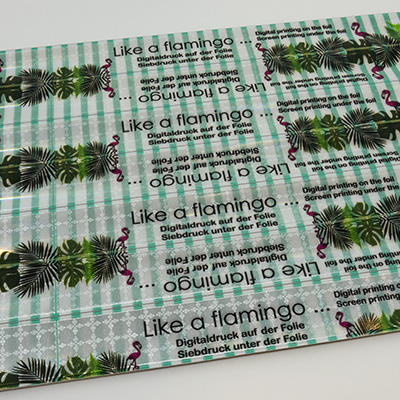

The films used in the production for our reflective products are from ORAFOL® or 3M. Orafol offers for pure promotion products which do not EN 13356.

The following film colors are available for this purpose:

- yellow (approx. Pantone 381)

- white (approx. Pantone 428)

- dark red (approx. Pantone 485)

- illuminating red (approx. Pantone 172)

- blue (approx. Pantone 286)

- pink (approx. Pantone 806)

- illuminating orange (approx. Pantone 1505)

Certified Films

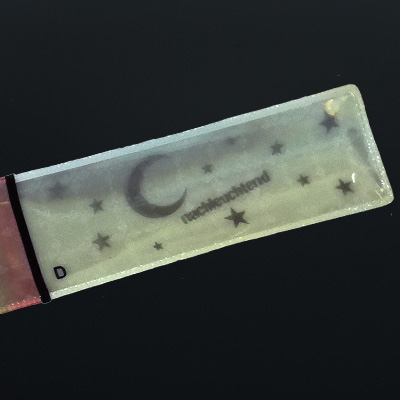

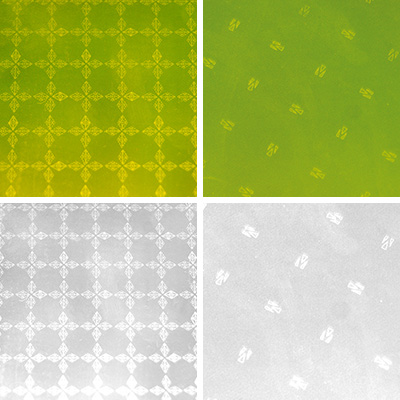

We use two different kinds of ORAFOL® film – films which are certified according to the standard EN 13356 in yellow and white or those from the coloured Classic films series. You can identify the ORAFOL® EN 13356 film from the pattern on the surface of the tape – a kind of snow flake design. The Classic films do not have a design.

Both types of films, the films certified according to EN 13356 and the Classic films are free from potentially hazardous phthalates.

The 3M films that we use which are certified according to EN 13356 (films colours – yellow and white) have a small „M“on the surface of the film (see illustration below).

The 3M films are available free of phthalates and with phthalates. The latter will only be used if specially requested.